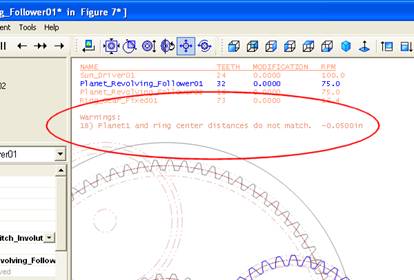

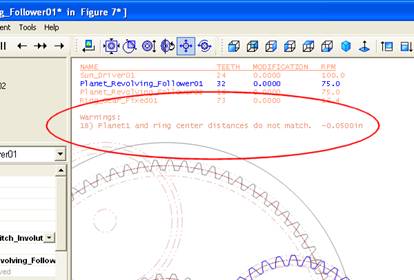

Alerts

GearTeq provides some alerts when it detects that something might be amiss with the current component’s design or with a set of components. This is not meant to be an all inclusive check. There may be problems with the design that GearTeq does not detect or alert the user about.

1 through 11 are not used.

12. The gear has no addendum modification. This may cause undercutting and/or tip interference with the mating gear.

13. The spiral angle of the bevel gear does not equal 0 or 35 degrees.

14. The bore diameter may be too large for this gear.

15. The backlash is greater than 1/4 of the circular pitch.

16. The pressure angle does not match mating parent.

17. Not used

18. The planet center distances are not matching.

19. The base diameter of the internal gear is larger than the minor diameter.

20. The pitch depth of rack is less than or equal to the dedendum.

21. The blank diameter of the internal gears is less than or equal to the major diameter.

22. Spiral bevel CAD models are not suitable for manufacturing. Please use them for documentation purposes only.

23. The internal gear has little or no negative addendum modification. This may cause tip interference with the mating gear.

24. Worm gear CAD models are not suitable for manufacturing. Worm gear CAD models created with the advanced tooth option are at least suitable for rapid prototyping.

25. There is a hub projection on side 1 but no diameter.

26. There is a hub projection on side 2 but no diameter.

27. There is a hub projection on side 1 specified but no diameter.

28. There is a hub diameter on side 2 specified but no projection.

29. The course pitch standard is selected but a diametral pitch finer than 20 is specified. The fine pitch standard is selected but a diametral pitch courser than 20 is specified.

30. The Module for the spline is not a standard increment.

31. A non-AGMA class is specified for an AGMA Spline.

32. The blank diameter of the internal spline is less than or equal to the major diameter.

33. The actual outside diameter is less than the specified diameter because of tooth shortening.

34. The rack addendum modification does not compliment the mating gear's addendum modification.

35. The web thickness is outside of the acceptable range.

36. Pinion number of teeth is less than that permitted by the Gleason standard.

37. Gear number of teeth is less than that permitted by the Gleason standard.

38. The total backlash for this component and its parent is outside of the range recommended by Gleason.

39. The hand of the mating gear does not compliment the current helical gear.

40. The standard set screw is set to true but a valid hub and a keyed bore are not specified.

41. Not used

42. Not used

43. The bore is larger than the minor diameter.

44. Timing belt CAD model of the active component is not suitable for manufacturing. Please use it for documentation purposes only.

45. The tooth thickness is less than recommended by the PGT standard.

46. The rack will not be created with the basic PGT rack radius ('sled runner' effect) added to the outer half of the addendum.

47. Special geometry ASA is specified but the chain pitch is set to 0.0000

48. Special geometry ASA is specified but the roller diameter is set to 0.0000

49. Heavy duty series sprockets with multi-strand are not available with this chain number.