|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Customers & CommentsAttention Customers!

Here's a few comments by some of our customers: ******************************** I've successfully applied the license and I'm pleased to say that the software is working smoothly. Thanks for providing such a reliable and user-friendly solution. Excited to continue using it and to see what's next! Nguyen, Quebec, Canada 2024-02-08 ******************************** Thank you for you incredibly fast response! After digging through and figuring out my companies security to allow me to run the SOLIDWORKS repair utility that solved my problem... Thank you again for you expert help, Steve 2023-01-13 ******************************** Hello, My Name is Alec A. and I'm the captain and drivetrain design lead of UMBC Racing. Camnetics has been a sponsor to our team for a few years now by providing your GearTeq for SOLIDWORKS software free of charge. The team is very appreciative of this generosity as it allows us to design our custom gearboxes which have always been some of the most light and efficient ones used in the series. For the 2023 season we will be resigning our gear ratios and geometry so we are once again in need of your software. As such we would like to request the latest version of your software for use with SOLIDWORKS 2021. Once again I'd like to thank Camnetics for their generosity and I've also attached our sponsor information package to this email. This packet goes over the benefits our sponsors receive for their contributions. If you need anything else from me to make this happen please don't hesitate to reach out. Thanks 06/27/2022 ******************************** You have always been fast and pro in the years I have had your product! Enjoy your Sunday! I'm making gears today! :-) ******************************** I've used GearTrax on many feature films and small projects. The ease of use and matching industry standards has made any gear related project a snap. ******************************** I represent the University of Maryland, Baltimore County SAE Mini-Baja team. First, I would like to thank Camnetics for its sponsorship of our team the past few years, your involvement has helped our small team maintain its Gearteq has been fundamental in improving our drive-train efficiency year over year, from 81% before you began supporting out team to a current efficiency of over 94%; a significant improvement for us, and critical in a stock engine racing series. CamTrax64 has allowed us to reverse engineer a component for our drivetrain which is no longer manufactured (originally scavenged from a snowmobile). Not only has this allowed us to maintain our performance by reproducing worn, irreplaceable components, but even begin research and development of custom profiles so that we can further optimize it to our unique needs, while reducing our operating costs by producing difficult components in house. These improvements in performance have enabled us to attain a 1st place award for research and design, a 3rd place award for fastest acceleration, and a 1st place award for lowest prototype cost. Results like these are a direct result of support from companies like yours, which allow us to thoroughly develop our ideas prior to fabrication. I am currently writing in hopes of continuing our partnership. Thank you, Daniel M ******************************** One again thanks for everything - I am awed by your engineering / programming talent and then you are friendly and helpful as well! ******************************** Thank You very much. You all have been very helpful. GearTrax is going to make my job a whole lot easier. Mike R. 2013-11-26 ******************************** Thanks for the fast answer. It is so simple and it really helped us. ******************************** Hello, ******************************** I was digesting your recommendations further. You have given us a really superb response on this, with very clear guidance. It's much appreciated! ********************************

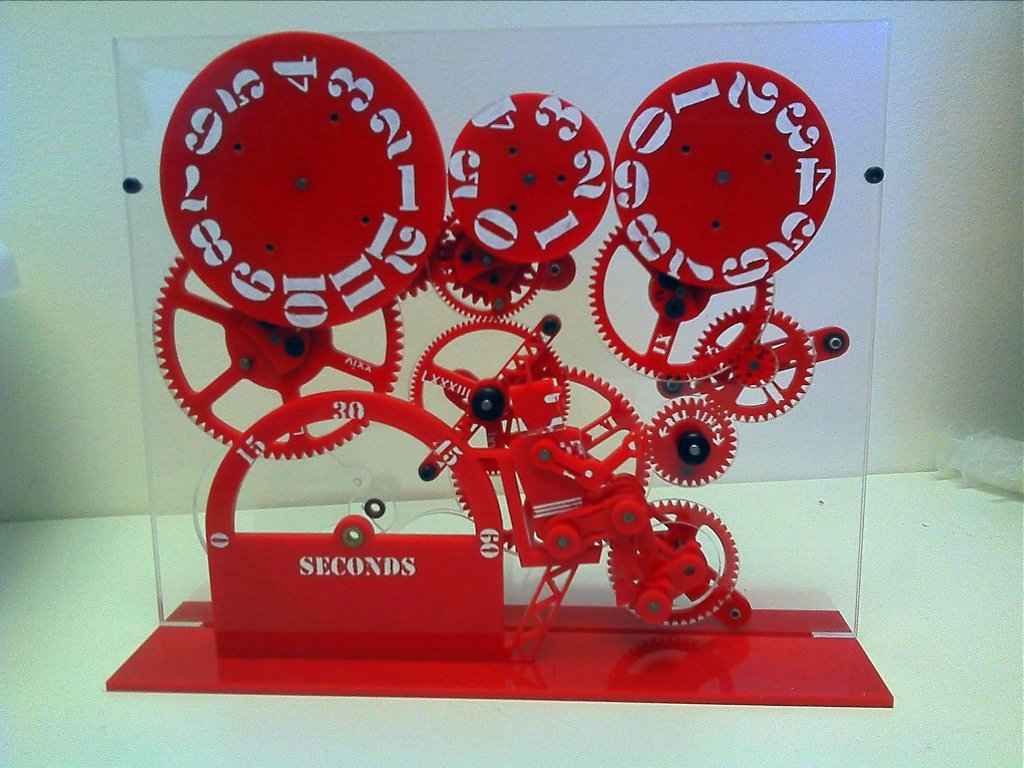

Cutting the parts for the MEISWINKEL JUMP HOUR CLOCK ******************************** Thanks for the quick reply again. I work for Johnson & Johnson and I have been recommending your product all over the company for years. Everyone here loves it (especially geartrax). It lets even our industrial designers design gears. Just thought you would like some positive feedback. ******************************** We are up and running thanks for the help your software (GearTeq) is a great tool for our department. ******************************** We are very pleased with the GearTrax software we purchased. We also have many cam applications and would like to evaluate CamTrax. Thanks. ******************************** Can you help me get an upgrade so that I can use your wonderful program with my upgraded SW 2011 ? ******************************** Most of our refurbished gear products, spurs and helicals are re-engineered using your software (GearTeq) and it has been very accurate and productive. ******************************** Greg, one thing is for certain, one of the best things in my machines is the gearing I make with your software! I freakin' love your software. Put me in a powder-blue suit with some over-moussed-hair: I'm ready to evangelize! I need to send you some things soon! If you don't know it already, I make some kick ass stuff with your software! ******************************** I also want to thank you for all your help and effort, the easy answer would have been to say this is what my software does, sorry it doesn’t work like you thought. You have gone above and beyond to help us solve our issues and keep this project alive. ******************************** From our conversation this morning and using the spur tab it looks like everything has worked out perfect on this. I'm going to practice with a few more but as of now I'm extremely impressed with the software. Thanks, ******************************** I would like to purchase a license for Gearteq. I had the trial a while ago, and was impressed. You also gave some really thorough support for a tricky problem I had. I now need to use it more extensively. ******************************** I have just realised that if I specify the Space_Width instead of Tooth_thickness, I can indeed get the final part exact. Excellent! Thanks for all your help. Best Regards, ******************************** Hey! I have GearTeq running! It's freaking gorgeous! Kent, Ph.D. Candidate (2009-10-21) ******************************** Whow, u'r fast! Thanks! (for providing new registration codes) Richard, Deerfield, IL ******************************** Thanks again for providing the best and fastest customer support.. ******************************** The software change has sorted my problem and has not introduced any other issues that I have noticed. Thanks a lot for this really quick response I am extremely impressed. May God's light shine on all your endeavours!!! Regards, Terry U.K. ******************************** Thank you for a fantastic program [GearTeq], I fell over backwards when it did a Anders, Sweden ******************************** Chris, W.Boylston MA ********************************* The GearTrax program worked beautifully for us in designing an external Thank you very much Regards Rick, Australia ****************************************** Shalom, Israel ****************************************** Thanks. I have it working. I'm just looking at a Spline that has been Best Regards ****************************************** Roger, Brockport, PA HI GREG, Thanks, for your great customer service. Best regards ****************************************** Thanks, Good update, I appreciate how GearTrax, which has always been useful, has become still more useful. Keep it up. Best regards, ****************************************** Here's a few of our customers:

MoldedGear.com LLC is an engineering consulting firm dedicated to helping clients with new product development and design; and the manufacture of metal and plastic gear transmission systems. Through the delivery of professional engineering design we create expanded applications for molded products, offer cost and time savings to our customers. We concentrate our efforts on various types of actuators and gearbox designs, including planetary or compound epicycle differential gears, cycloid, non-circular, crossed axis helical gears, face gears, lantern-crown gear, spiral bevel gears, worm and external and internal spur gears.

|